Secure networked systems – the pathfinders for Industry 4.0

Monitoring of high-end production equipment is a central aspect of Industry 4.0. Within Munich’s High Performance Center for Secure Connected Systems, Fraunhofer EMFT – together with Edwards GmbH and the Fraunhofer institutes ESK and AISEC – is working on establishing improved characterization for status monitoring of vacuum pumps.

The High Performance Center for Secure Connected Systems (SVS) offers its partner companies an interdisciplinary and application- oriented environment for systematic research in the areas of Industry 4.0, networked mobility, and smart health / smart homes. Edwards is a partner in the Industry 4.0 sector and a leading developer and manufacturer of modern vacuum products, exhaust cleaning solutions, and associated added-value services. With the PAMP (Predictive Advanced Maintenance for Pumps) project, the British company has been in a strategic partnership with SVS since the end of 2017. The project’s specific focus is on status monitoring of high-quality vacuum pumps used in semiconductor production in conjunction with processing equipment. Digitization in production makes the step from preventive to predictive maintenance possible.

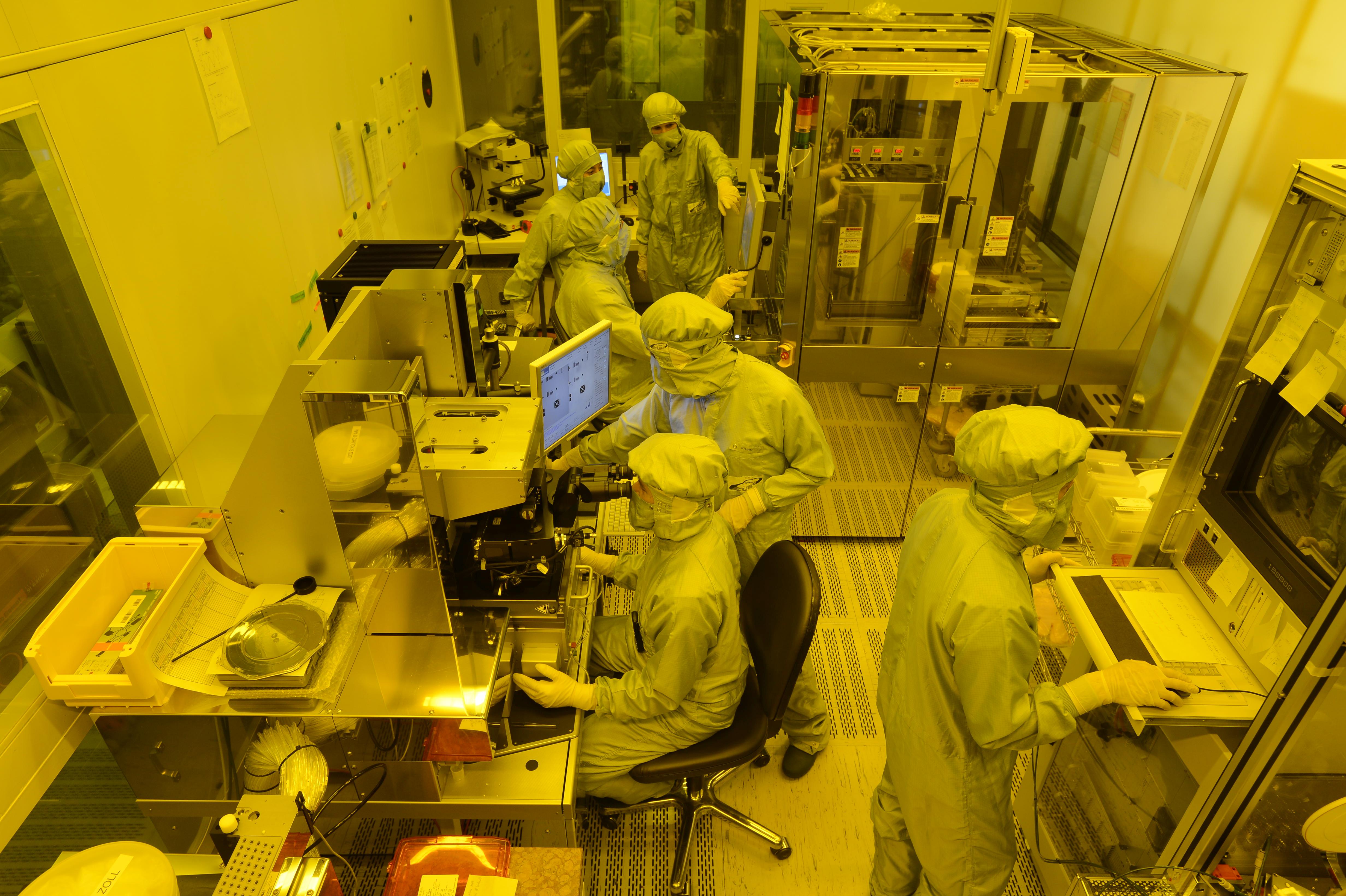

Fraunhofer EMFT cleanroom as a test environment

One emphasis of the work is on investigating the connection between process flows and pump behavior. The 200 mm CMOS semiconductor line at Fraunhofer EMFT, together with the many years of growing knowledge of process development and semiconductor manufacture among employees, offers the optimum environment for the monitoring of equipment in conjunction with vacuum pumps and correlation analysis. This can be taken as a starting point to improving the performance and service life of the components. The experts from Fraunhofer ESK and AISEC will develop secure and flexible communication solutions for networked factories. Among the items planned is a sensor set-up in Fraunhofer EMFT’s cleanroom environment, which can be used to capture data from different positions within the infrastructure, as well as the preparation of a connected sensor node network, including a secure Internet of Things (IoT) infrastructure. In order to detect anomalies in the sensor data and to optimize the performance of the pumps, the project partners would also like to deploy innovative machine learning techniques.

Secure connection allows cross-location communication

Another important aspect is the use of secure, highly reliable wireless communication between devices, taking into account factors such as energy consumption, data throughput, data volume, and the specific requirements of a semiconductor manufacturing environment. This means that a secure connection needs to be implemented to exchange data, machine learning models, and the device status in real time between secure locations: on-site on the Fraunhofer EMFT CMOS line, remotely in the cloud, or at the Edwards company headquarters. This approach simplifies the development and deployment of analytical models while also reducing service response times. The aim is to provide a new reference architecture that fulfills the requirements of Industry 4.0 while also being tailored to the unique IP needs of semiconductor manufacturers.

Last modified: