New standards in positioning accuracy

Connected automated driving needs highprecision positioning systems. That is why, together with several industrial partners, Fraunhofer ESK tested new positioning technologies on the A9 digital freeway test track. For the first time, it was possible to obtain positioning accurate to the nearest centimeter throughout the test session, even at higher speeds.

This level of precision was attained during the test drive thanks to high-quality correction data. One particular challenge was in supplying the information efficiently and in real time. Multi-access Edge Computing (MEC) technology was tested as part of the trial and was compared with other technologies. MEC allows the simultaneous dissemination of regionalized correction data to all vehicles in a specific area. This reduces network traffic and is more cost-efficient.

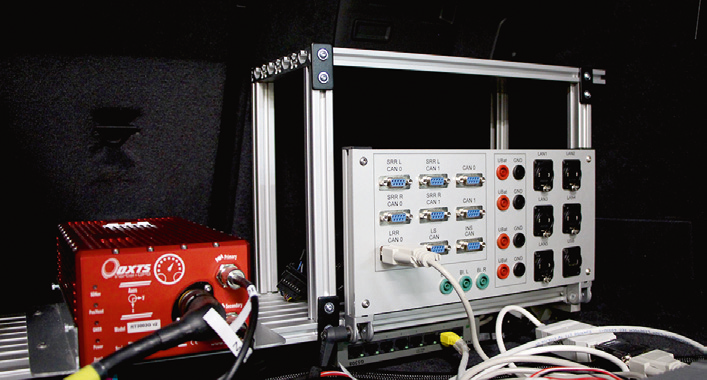

Fraunhofer ESK designed and integrated the end-to-end connectivity solution, provided its VICTOR test vehicle equipped with test and reference receivers, and helped evaluate the data. In the next step, the partners intend to optimize the robustness of the receivers. They will continue the research by extending the test drives to the entire mobile network and by adding different driving maneuvers and speeds.

In addition to Fraunhofer ESK, Deutsche Telekom, Nokia, and Hexagon Geosystems were also involved in the project.

Last modified: